Sustainability at KuchenMeister

KuchenMeister has always stood for tradition, quality and innovation.

As early as 1961, when the first manufacturers began to use water instead of expensive milk in the production of wafer rolls, Günter Trockels remained true to its tried and tested, high-quality recipes. High-quality raw materials, efficient machines and the sustainable use of resources have always been part of our corporate philosophy.

Find out more about our certified raw materials, our product quality and our sustainability plan below.

Further information on our sustainability topics can also be found on our press page, for example.

Sustainable goals 2024

Social

As the health of our employees is important to us, we have set ourselves the target of reducing the number of accidents at work by at least 5% by 2024.

Ecological

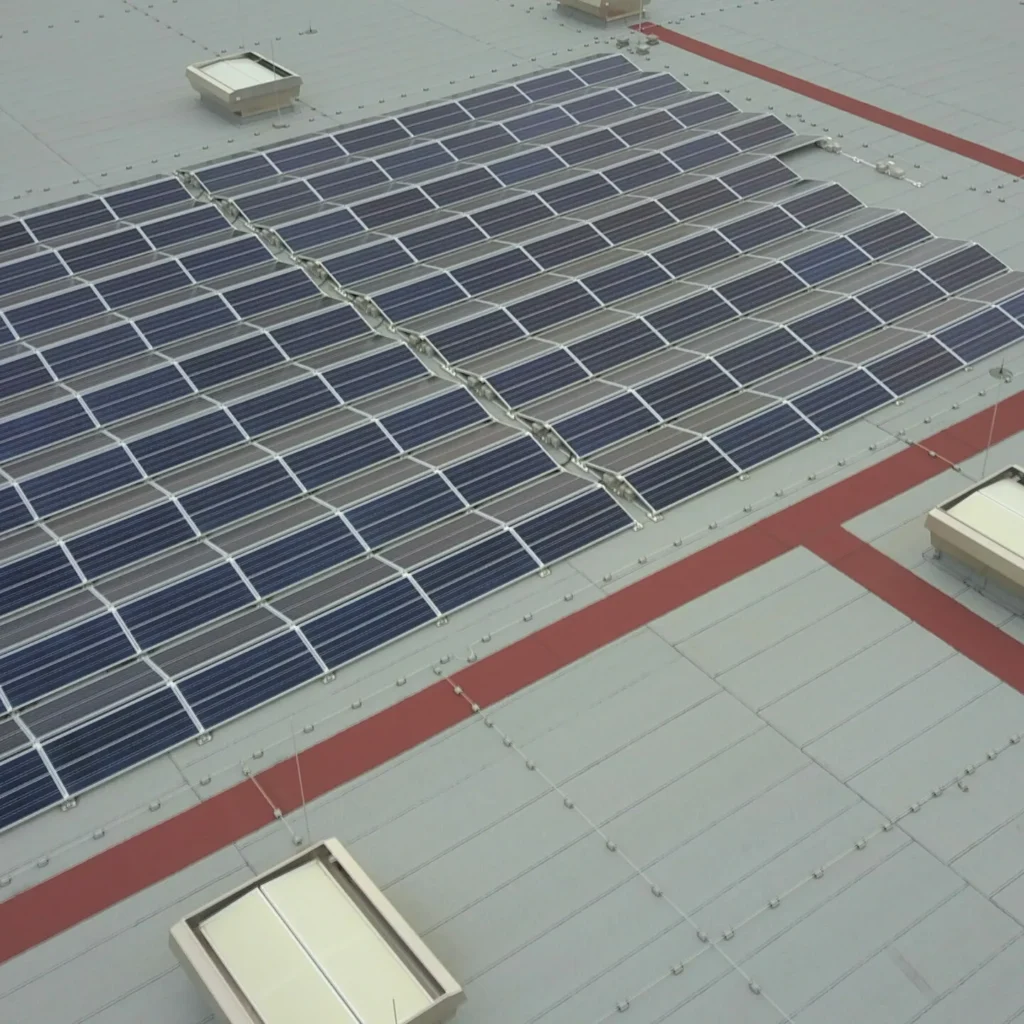

By expanding our photovoltaic systems, we wanted to increase our output from this renewable energy by 750% by the end of 2024. In theory, we have achieved this target, although not all systems are yet connected to the grid due to regulatory requirements.

Economic

A Giga-Liner was deployed for shuttle transport between our two production sites in Soest and Thüle in time for the 2024 stollen season. This means that an average of 35% more goods can be transported each way. This will save a third of the original journeys during the cake base and stollen season. After a test phase lasting several months, it has been in regular 3-shift operation since 01.01.2025.

Sustainability at KuchenMeister

“The topic of sustainability brings a wide range of added value for society, but also for our company as a whole. We must therefore continue to develop our sustainability work at KuchenMeister together with our employees, suppliers, customers, retailers and all other members of our society.”

Hans-Günter Trockels, Managing Director of KuchenMeister GmbH

Our site at the old sugar factory covers 17 hectares. Here we make various contributions to biodiversity and at the same time create a functioning coexistence between industry and the environment.

A small, but very nice project is the establishment of 16 bee colonies on our premises - naturally looked after by an experienced beekeeper. We have planted 52 fruit trees on the site for these bees. In addition, there are 80 native deciduous trees in various areas of the site. They also find food in our wildflower meadows.

Sheep are our additional lawnMÄHer - and we also have a place for black sheep. The small herd alternates between different meadow areas.

In August 2023, KuchenMeister was awarded the Soest Climate Protection Prize for its biodiversity concept. You reinvested the prize money in the redesign of another area on the company premises in cooperation with NABU. The area was completely redesigned to make it as close to nature as possible. This includes, for example, the use of a regional Soest flower seed mixture that was specially developed for native wild bees. In addition, self-built insect hotels, holes in the ground and piles of stones make the area a refuge for insects and a wide variety of small animals. When selecting the area, we paid particular attention to the existing natural infrastructure. A nearby fire pond serves as a source of water for insects and animals and trees that have already been planted provide natural shade. We have also installed information boards and seating in the area for employees who like to use their lunch break for a short walk.

The people in a company shape and carry the specific work and character that it has. KuchenMeister is traditionally owner-managed, meaning that the owner family sets the guiding principles. Within this framework, however, employees are offered a wide range of development and creative opportunities - for themselves, for their tasks and for the company.

We embrace diversity, we value the experience of long-standing employees, we encourage fresh ideas from young people and we always try to create good working conditions for individuals. One of our goals is to support the compatibility of family and career. More than 1000 employees guarantee a wealth of expertise, dedication, talent and creativity. People of around 52 different nationalities work together. 55 apprenticeships in 11 professions offer young people a good start to a successful career.

By supporting sporting activities, such as a job bike and company runs, we aim to actively support the health of our employees.

We took a big step with our entire administration in 2021. Around 100 people moved into the new administration floor with an open-space office at the sugar factory.

Protecting the environment from greenhouse gases is an increasingly important factor for companies.

Wir arbeiten kontinuierlich daran, Energieeisparpotentiale zu erkennen, zu reagieren und die Verbräuche zu senken. Durch unsere ISO 50001 – Zertifizierung We are constantly working to identify potential energy savings, respond and reduce consumption. Our efforts are reviewed annually by an external auditor.

For example, we are increasing the amount of electricity we generate ourselves by using photovoltaic systems and combined heat and power plants. By purchasing green electricity, we are reducing our CO2 footprint.2-Fußabdruck.

Measures such as heat recovery systems or 100% LED lighting (some of which is made from recycled shampoo bottles) help to reduce our energy consumption.

In 2009, we acquired the brownfield site of the “old sugar factory” and are constantly expanding it. Various sustainable aspects were taken into account during the construction of the hall complex. Thanks to the increased roof thermal insulation, the KfW55 standard was achieved and undercut, and insulating ISO-ROCK concrete was also used. Insulating floor slabs and triple-glazed windows were also used. The waste heat from our ovens is used to heat the building. And, of course, our office building has a photovoltaic system.

The outdoor area was also designed to be sustainable. More than 300 tree trunks, which were classified as unprocessable in a sawmill, were used to create more than 2,000 m of roadway and site boundaries. 580 square meters of basalt paving from an old barracks in Soest found their way to the sugar factory. This gave the sidewalks and squares a character all of their own.

Further activities can be found under “Biodiversity”.

Good raw materials, convincing recipes, excellent quality - a good description of what we bake every day.

Since 2019, we have only processed 100% palm oil RSPO SG-zertifiziert.

Der Kakao in vielen unserer Produkte ist seit 2022 nach Rainforest Alliance zertifiziert.

Since 2015, we have been certified for cocoa FairTrade zertifiziert.

The ZNU standard (Center for Sustainable Corporate Governance) is a framework that supports companies in integrating sustainable practices into their business strategies. It promotes a holistic view of ecological, social and economic aspects and helps companies to assume their responsibility towards the environment and society.

Overall, ZNU certification helps to ensure long-term success and strengthen a company's resilience in a changing market environment.

Since 2012 we have been ZNU certified.

At KuchenMeister, we have currently decided against offsetting our emissions and are instead focusing on reducing our footprint.

Our sustainability report

KuchenMeister has been committed to progress and further development in terms of sustainability for over a decade. This is why KuchenMeister regularly publishes a sustainability report in which, for example, we disclose the measures we are taking to protect the climate and save energy. In addition, KuchenMeister sets itself fixed targets for the coming years each time. The current sustainability report offers a detailed insight into many topics that KuchenMeister deals with on a daily basis, as sustainability does not only refer to climate protection, but also affects many different areas of the company.