Sustainability at KuchenMeister

KuchenMeister has always stood for tradition, quality and innovation.

As early as 1961, when the first manufacturers began using water instead of expensive milk in the production of wafer rolls, Günter Trockels remained true to the proven, high-quality recipes. High-quality raw materials, efficient machines and the sustainable use of resources have always been part of our corporate philosophy.

Learn more about our certified raw materials, product quality and sustainability plan below.

Further information about our sustainability topics can also be found on our press page.

Our Sustainable Goals

Social

Since the health of our employees is important to us, our goal for 2024 was to reduce the number of our occupational accidents by at least 5%. Our goal for 2025 is to introduce occupational health management to increase employee health and satisfaction.

Environmental

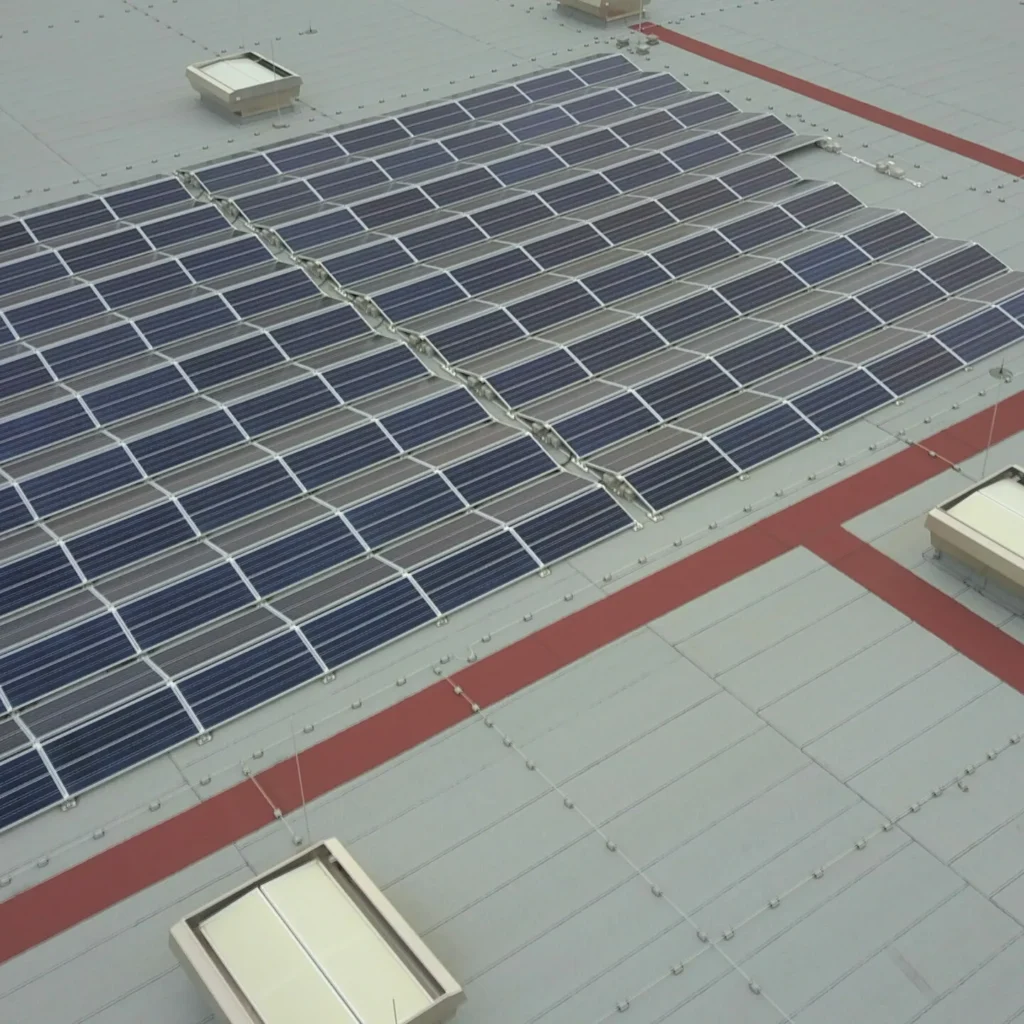

By expanding our photovoltaic systems, we wanted to increase our output from this renewable energy by 750% by the end of 2024. Theoretically, we achieved this goal, but not all systems are yet online due to official documents. Our goal for 2025 is to introduce a system for determining more needs-based products through customer surveys and sensory tastings.

Economical

For the 2024 stollen season, a Giga Liner was used for shuttle traffic between our two production sites in Soest and Thüle. As a result, an average of 35% more goods can be transported per trip. This saves one-third of the original trips in the cake base and stollen season. After several months of testing, it has been operating on a regular 3-shift basis since 1 January 2025. For 2025, we aim to optimise our recycling concept with the help of a local provider.

Sustainability at KuchenMeister

At KuchenMeister, we are convinced that entrepreneurial success and environmental and social responsibility are inextricably linked. Our goal is to create sustainable solutions that both protect our environment and strengthen society.

Our site at the old sugar factory is 17 hectares. Here, we make various contributions to biodiversity while also fostering effective cooperation between industry and the environment.

We also manage a settlement of 16 bee colonies as a small but mighty project – supervised by an experienced beekeeper, of course. We have planted 52 fruit trees for these bees on the site. Additionally, there are 80 native deciduous trees in various areas of the site. They can also find food in our wildflower meadows.

Sheep are our supplemental lawn mowers; with us, black sheep also find their place. The small herd alternates between the different meadows.

In August 2023, KuchenMeister was awarded the Soest Climate Protection Award for its biodiversity concept. You have reinvested the prize money gained in the redesign of another area on the company premises in cooperation with NABU. The area has been completely reprocessed to create a design as close to nature as possible. This includes, for example, the use of a regional Soester flower seed mixture, specifically developed for local wild bees. Furthermore, the area has become a retreat for insects and various small animals thanks to man-made insect hotels, burrows and piles of stones. When choosing the area, we paid particular attention to the existing natural infrastructure. A nearby cooling pond serves as a water source for insects and animals, and already planted trees provide natural shade. Additionally, we have installed information boards and seating here for employees who like to use their lunch break for a short walk.

The people in a company shape and sustain the specific work and its character. KuchenMeister is a traditional owner-managed business, so the guide post is set by the owner’s family. Within this context, however, employees have a wide range of development and design opportunities – for themselves, for their task and for the company.

We embrace diversity. We value the experience of long-term employees. We promote the fresh ideas of young people. We always strive to create good working conditions for everyone. One goal is to support the establishment of a work-family balance. More than 1,000 employees guarantee a wealth of competence, commitment, talent and creativity. About 52 different nationalities are working together. 55 apprenticeships in 11 professions offer young people a good start to a successful professional life.

By supporting sporting activities, such as a job bike and company runs, we actively encourage the health of our employees.

Our entire administration team took a big step in 2021. Around 100 people have moved into the open-space office on the new administrative floor at the sugar factory.

Protecting the environment from greenhouse gases is becoming increasingly important to companies.

We are continuously working on identifying energy-saving potentials, reacting and reducing consumption. As part of our ISO 50001 certification, our efforts are reviewed annually by an external auditor.

Through the use of photovoltaic systems and combined heat and power plants, we are increasing our share of electricity generation. By purchasing green electricity, we reduce our carbon footprint.

Measures such as heat recovery systems and 100% LED lighting (some of which are made from recycled shampoo bottles) help reduce our energy consumption.

In 2009, we acquired the brownfield site of the old sugar factory and have been expanding it ever since. Various sustainable aspects were taken into account in the construction of the hall complex. Due to the increased roof thermal insulation, the KfW55 standard was attained and undershot, and insulating ISO-ROCK concrete was also used. Insulating floor slabs and triple-glazed windows were also used. The waste heat from our stoves is used to heat the building. And of course, our office building has a photovoltaic system.

The outdoor area also follows a sustainable design. More than 300 logs, which were classified as not processable in a sawmill, resulted in more than 2000 m of scheduling and space restrictions. 580 m² of basalt paving from an old barracks in Soest was brought to the sugar factory. Sidewalks and squares have taken on a character all their own.

Further actions can be found under Biodiversity.

Premium raw materials, compelling recipes, excellent quality – a good description of what we bake every day.

Since 2019, we have been processing palm oil exclusively with 100% RSPO SG certification.

We have been Fair Trade Certified for cocoa since 2015.

Since 2013, we have exclusively used barn-laid eggs and egg products.

The ZNU Standard (ZNU, Centre for Sustainable Business Management) is a framework that helps companies incorporate sustainable practices into their business strategies. It promotes a holistic view of ecological, social and economic aspects and helps companies assume their responsibility towards the environment and society.

Overall, ZNU Certification helps ensure long-term success and strengthens a company’s resilience in a changing market environment.

We have been ZNU certified since 2012.

Currently, at KuchenMeister, we have decided against compensating for our emissions, but are focusing on reducing our footprint.

Our Sustainability Report

KuchenMeister has been committed to advancing sustainability for over a decade. That is why KuchenMeister regularly publishes a sustainability report that, for example, discloses the measures we are taking to protect the climate and save energy. Furthermore, KuchenMeister sets firm goals every year. The current sustainability report offers detailed insight into many topics that KuchenMeister addresses on a daily basis, as sustainability not only relates to climate protection but also affects many areas of the company.